Are you having trouble with your feed dogs not pulling your fabric through? Learn the common causes of this annoying problem and how to remedy it!

When sewing any project, from a quilt to a dress, it is important that it is pulled straight and even through the sewing machine. That’s what the teeth on your feed dogs are for: grabbing the material and gently moving it under the needle and towards the back of the machine.

But what if your fabric just won’t move? The most common reasons sewing machine feed dogs fail to move fabric are that the feed dogs are dropped, the stitch length is too low, or the material is too thick.

But these aren’t all the reasons! Let’s go through the other possible reasons this problem happens, and learn what to do to fix it!

5 Reasons Why Your Feed Dogs Are Not Moving Fabric

1. Your Feed Dogs Are Dropped

Let’s start with the first and easiest to solve!

If you are new to sewing you may not know that feed dogs are capable of being raised and lowered depending on if you need to utilize them for the particular item you are sewing.

When free motion quilting for example, you would drop the feed dogs to allow you to move the fabric in any direction you choose.

When the feed dogs are dropped (or lowered) they are temporarily moved down under the needle plate. An easy way to check this is to run your hand over the feed dog area as you turn the hand wheel, if you can feel them rub against your fingers, they are in the raised position. If you can’t feel them, they are lowered.

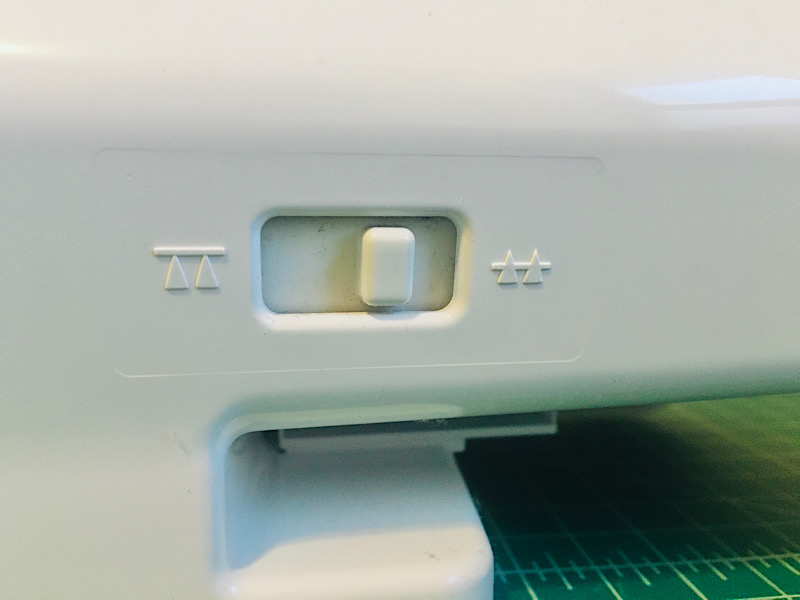

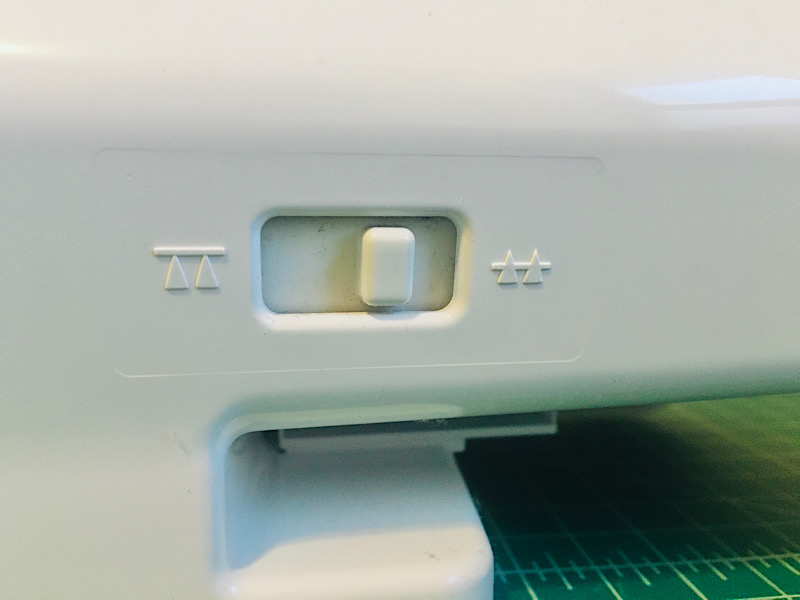

You can look on the back (or side) of your machine to locate the feed dog lever. This lever is a little switch that lifts and drops the feed dogs.

Slide the lever left and right to raise and lower the feed dogs and allow them to engage or disengage with your fabric.

2. The Stitch Length Is too Low

When you adjust the stitch length on your sewing machine you are actually reprogramming the feed dogs to move at a slower or faster rate. The speed your fabric is pulled through determines how often the needle will be able to pierce through the material, and how close the holes will be to each other.

If your stitch length is too low, the material is not being pulled through very fast because the needle needs to make the holes close together to make very small stitches.

In addition, if the stitch length is set to zero then the fabric won’t be pulled through at all, even if the feed dogs are NOT dropped.

So make sure the stitch length is set to the default number (this differs for different machines, you can check your manual or try a 2.5 which is what my machine is set to) and see if this helps your fabric move better.

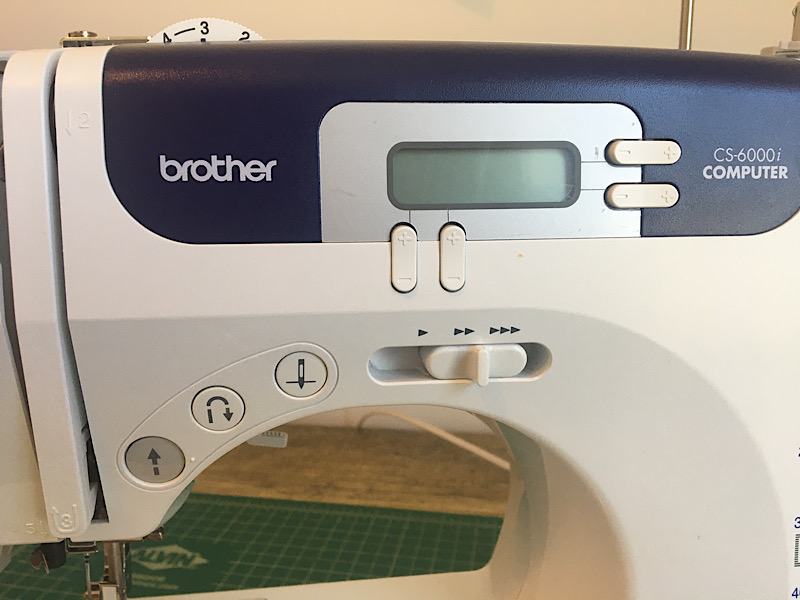

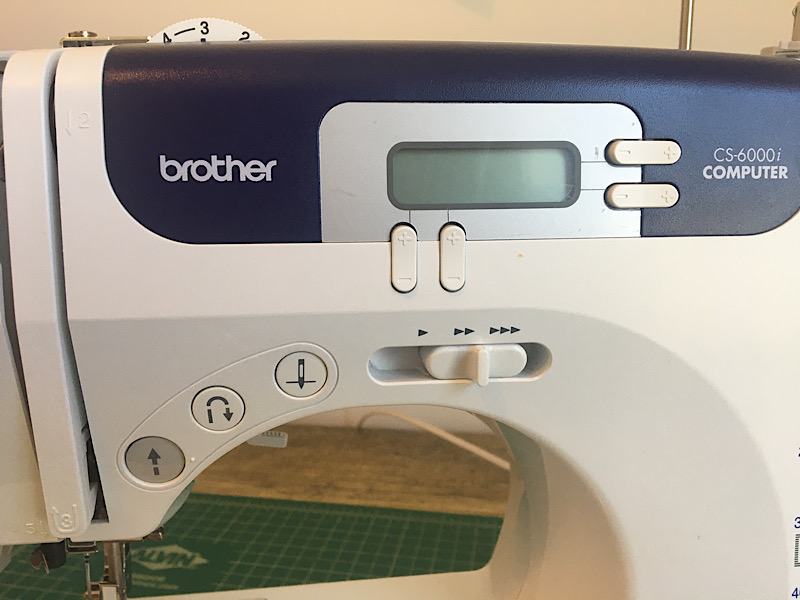

If you are new to sewing and don’t know how to change the stitch length, the buttons are usually on the front of the machine and have a plus and minus symbol like in the photo above.

3. Your Fabric Is Too Thick

Very thick materials and especially materials that are layered (such as quilts!) can be too thick for the feed dogs to move. The feed dogs’ teeth grab the fabric, but it is too heavy to be pulled through and remains in the same spot.

There is an easy solution for this problem, and it is to use a walking presser foot.

A walking presser foot is a VERY cool tool, and you can learn about them in my presser foot guide.

Walking presser feed are basically a second set of feed dogs meant for the TOP of the fabric. Because the top and the bottom of the fabric is grabbed pulled through simultaneously, the fabric is much easier to move and flows right through the sewing machine.

Walking presser feet are essential for quilts, and thick materials like jeans, towels, etc.

They aren’t hard to use, although they do kind of look like a hermit crab!

4. Your Fabric Is Too Slippery

Sometimes really thin or slippery fabric is hard to sew because the feed dogs have trouble grabbing it (and it sometimes gets ‘sucked’ down into the needle plate!)

If this is your problem, you can help the feed dogs to grab and move the fabric by stiffening it up or adding something to temporarily make it thicker. Here are some ideas:

- Try increasing the presser foot pressure

- Try sewing the fabric with some tissue paper or stabilizer or washi tape underneath it (on top of the feed dogs) and then tearing it away after stitching.

- Try spraying starch on the fabric to stiffen it up.

You can also try to increase the presser foot pressure to make it higher so that the fabric is held more tightly down towards the feed dogs instead of slip-sliding right through.

5. The Presser Foot Pressure Is Too High

On slippery or thin fabric you might have to increase the presser foot pressure, but if the pressure is too high then it can prevent the fabric from moving due to being held down too forcefully.

Every machine is different when it comes to changing the presser foot tension, height, and pressure. If you have a computerized model there may be a button setting you push, otherwise there may be a screw on the presser foot or needle housing, or a dial you turn on the back of the machine.

You will have to look at your manual to find your specific instructions! (Tip, if you have lost your manual like I have, you can search for an online copy!)

Conclusion

The problem of sewing machine feed dogs refusing to move fabric while you sew is an annoying one! It can result in uneven and wobbly stitching, knots in the stitching, and even a broken needle if you sew too many times in the same spot or have to jerk the fabric through.

If it turns out that none of these solutions worked for you, make sure to read the other reasons a sewing machine won’t move fabric (feed dogs are only one part of this issue!)

You can learn more about the feed dogs on your machine and how they work in my All About Feed Dogs Sewing Guide.

I hope these 5 common causes and solutions to this problem was helpful for you, let me know in the comments below which one helped you the most!

thanks so much for this piece,it was really helpful.

You are welcome, I’m glad it was useful to you!

Thanks very much. The presser foot helped me

Im so glad!