Feed Dogs–the understated but important work horse (or dog) of your sewing machine. What are they? How do you fix them? And why do they have such a strange name?

Feed dogs are one of the vital and basic parts of your sewing machine. Not only to the movement of your fabric while sewing, but also to the length and timing of your stitches and their consistency.

This post will teach you the basics of proper feed dog function and help you figure out what is wrong with them!

This post may contain affiliate links. Read the full disclosure here.

What Are Feed Dogs?

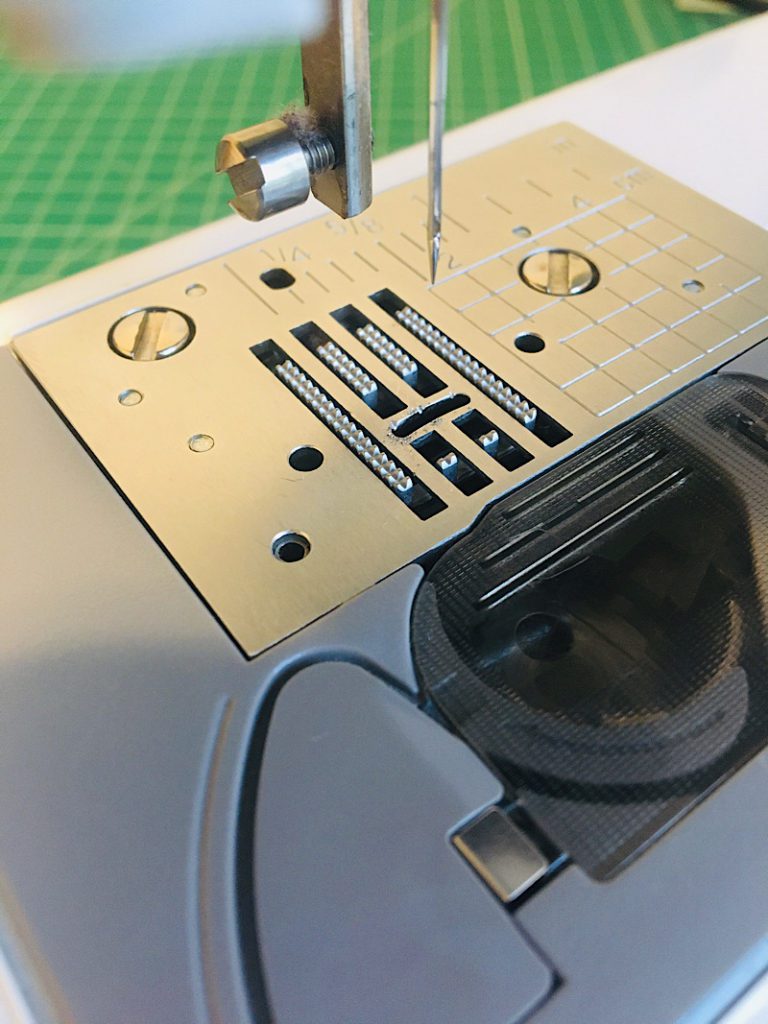

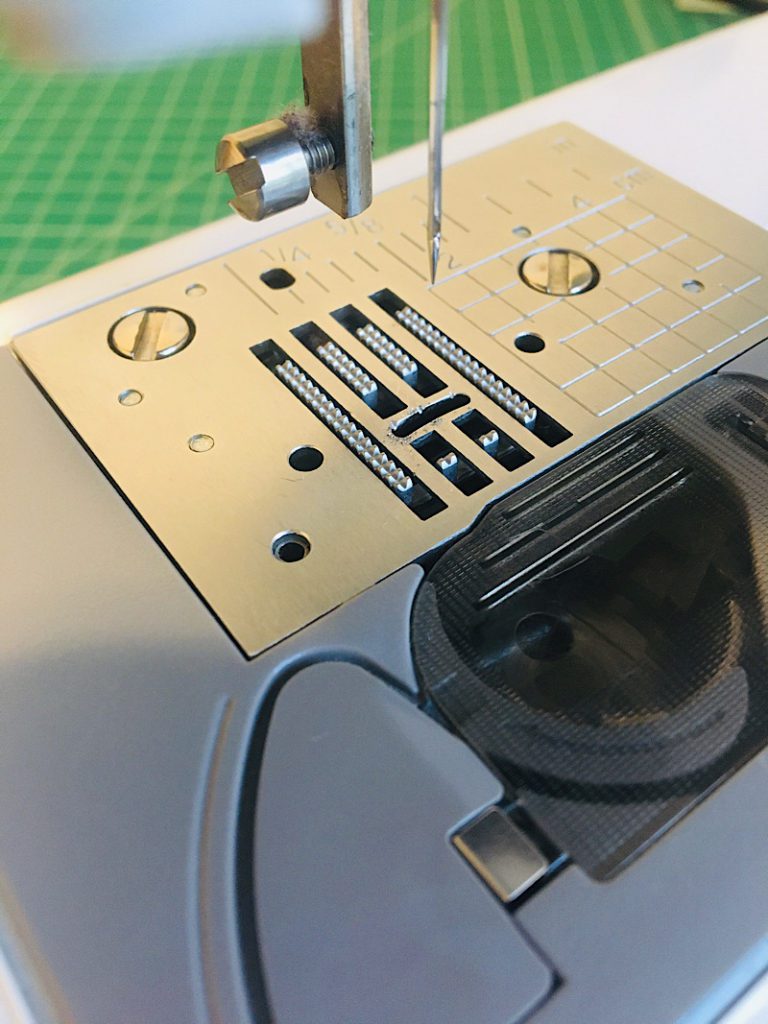

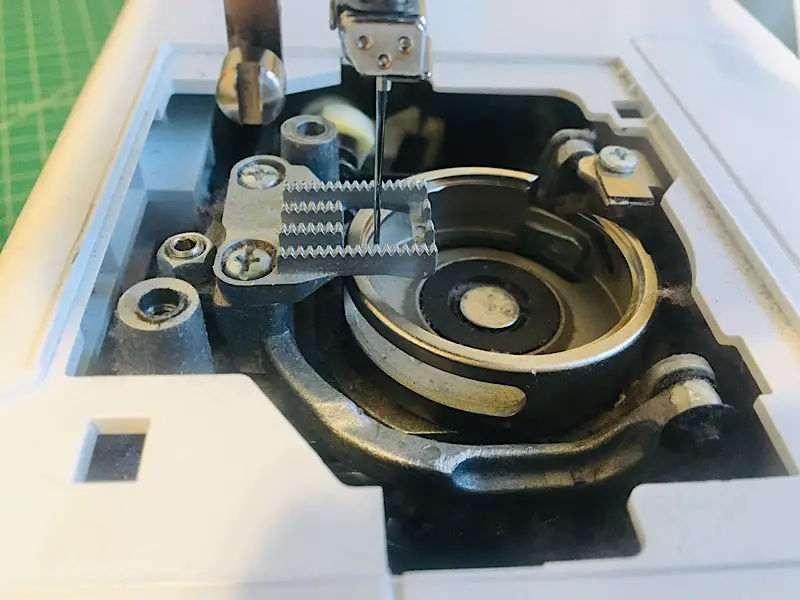

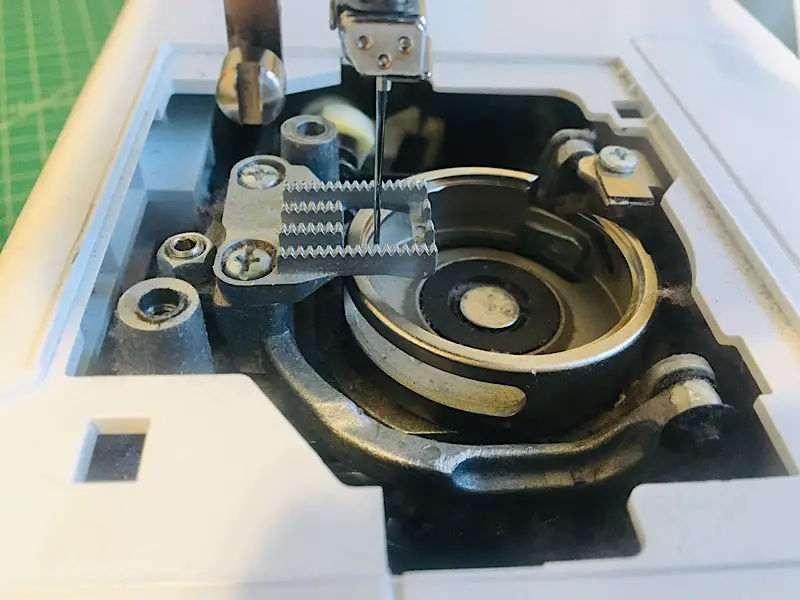

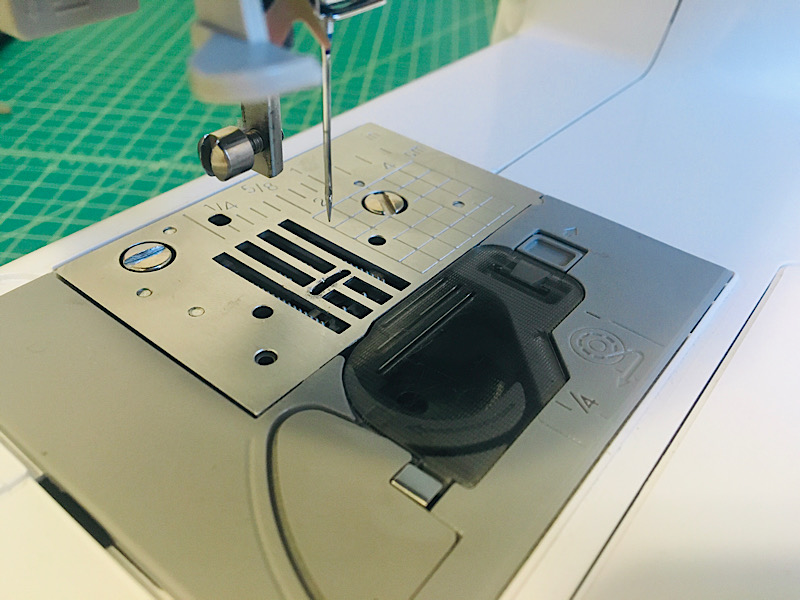

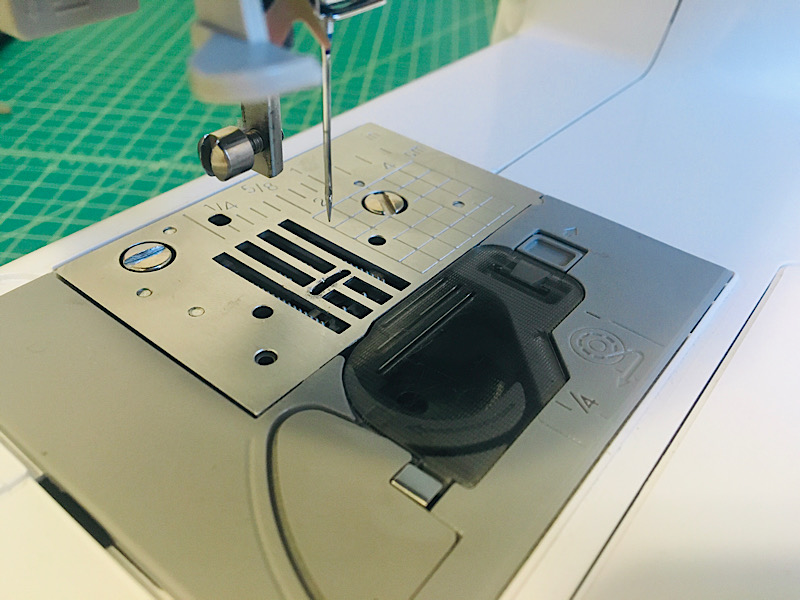

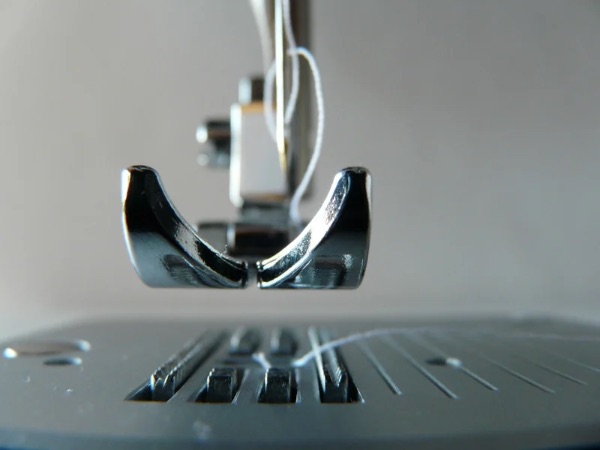

Feed dogs are the toothed metal bars located under the needle plate, that grip the underside of your fabric as you sew. As you sew, the feed dogs move in an up and down, front to back motion to gently pull your fabric through the machine. They raise and lower through slots in the needle plate.

Feed dogs can be manually dropped through a button on your sewing machine if you need more free motion capabilities or have fabric that is too thick or too thin.

The diagonal teeth on the feed dogs are pointed enough to gently grip and pull the fabric, but not sharp enough to tear. However, if you are sewing with a very thin or delicate material such as lace, or have your presser foot pressure too tight, the feed dogs can snag on your fabric.

Feed dog problems on sewing machines and sergers can cause bunching, skipped stiches, or fabric that doesn’t feed through straight.

Why Are They Called Feed Dogs?

The name “Feed Dogs” comes from the motion of the bars “feeding” or pulling the material through the machine under the needle. The word “dogs” is an engineering term that describes a machine part which “imparts movement through physical engagement”.

The term dogs is possibly derived from the idea of a canine’s sharp teeth which bite and lock onto an object.

In the late 1800’s the terms “Feed Bar” and “Feed Points” were used. Threads Magazine states that:

By 1915, “feed dog” is in the handbook for the Singer No. 115. The feed dog, thus, is older than its name.

Threads Magazine

Are you having trouble with your feed dogs? Lets troubleshoot some common issues below…

Why are my feed dogs not moving my fabric?

Feed dogs might have trouble moving fabric for several reasons: for example they are in the “dropped” position, the fabric is too thick, or your stitch length is set to zero.

1. Thick Fabric

Thick fabric can prevent the needle from working properly, causing fabric to drag, snag, or even prevent it from being pulled by the feed dogs at all. You can try using a walking foot to help feed it through correctly.

Incorrect timing can also affect how thick fabric is gripped by the feed dogs.

2. Feed dogs or presser foot needs to be adjusted.

Some sewing machines have adjustable feed dogs. If the feed dog height is too low, they may not raise high enough above the needle throat plate to grip the fabric.

Check your sewing machine’s manual to see if your feed dog height can be adjusted.

In addition, for your feed dogs to work your presser foot needs to be exerting enough pressure.

When the presser foot has enough pressure, the fabric is held in place for the feed dogs to grab. Otherwise, it might just slip through.

This happens especially when you are using very thin or slipper materials like silk.

3. Stitch Length

If your feed dogs are not moving at all, make sure that your stitch length is not set to zero.

The stitch length tells your machine how far to pull the fabric through before lowering the needle again. If your stitch length is set to zero, your feed dogs will not move. Usually, a stitch length of 0 with dropped feed dogs is used for free motion quilting.

4. Feed dogs are stuck in the dropped position.

If your feed dogs are dropped or stuck in the dropped position, they will not be able to move your fabric. Read the next section to learn how to drop, fix and raise them!

How Do You Lower The Feed Dogs on a Sewing Machine?

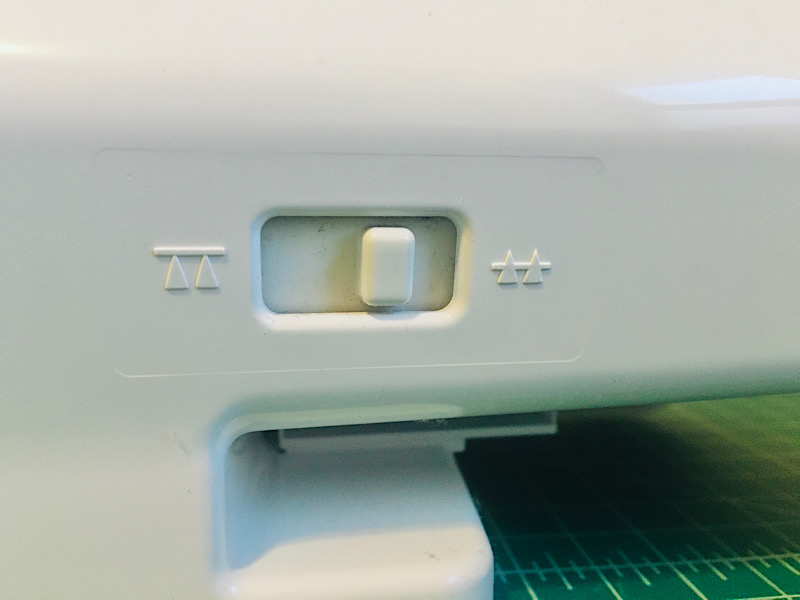

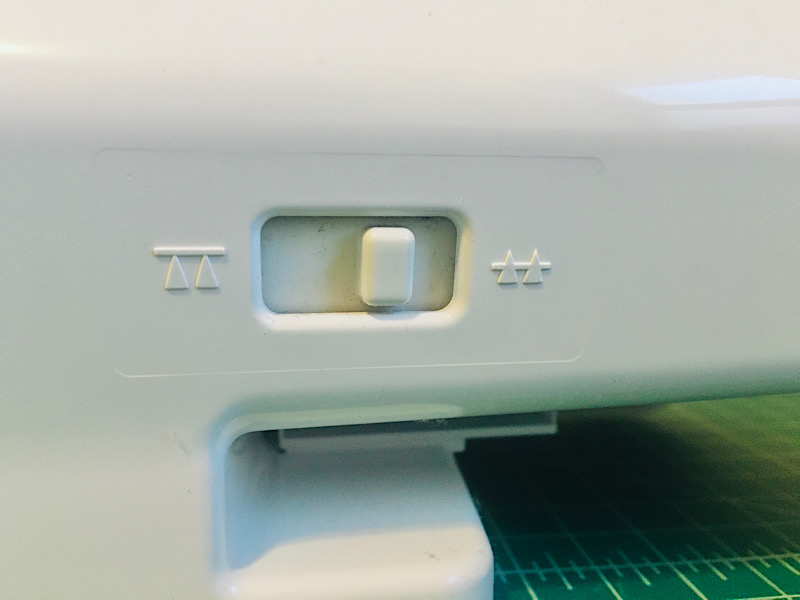

To lower or drop your feed dogs, locate the button or switch on the back or side of your sewing machine and move it to the ‘dropped’ position.

To raise your sewing machine feed dogs, locate the feed dog switch and move it to the raised position.

On my sewing machine the feed dogs dropped symbol is on the left; with the triangles representing the dogs underneath the plate.

If you cannot locate the switch, look inside your sewing machine manual. It should have a chart of your sewing machine and help you locate each part of it.

What Do I Do if my Feed Dogs are Stuck?

If your feed dogs seem to be stuck in the down position, there are a few things you can try.

1. Turn The Hand Wheel

Try turning the hand wheel (also called a balance wheel) on the right side of your sewing machine a few times to raise and lower the needle.

This will help you make sure the feed dogs are actually dropped, and not just on the downward motion of their movement.

2. Check your feed dog height

As I mentioned before, some sewing machines have adjustable feed dogs that can be raised higher to get a more precise fit for your needs.

Check in your manual to see if your machines feed dogs can be manually raised.

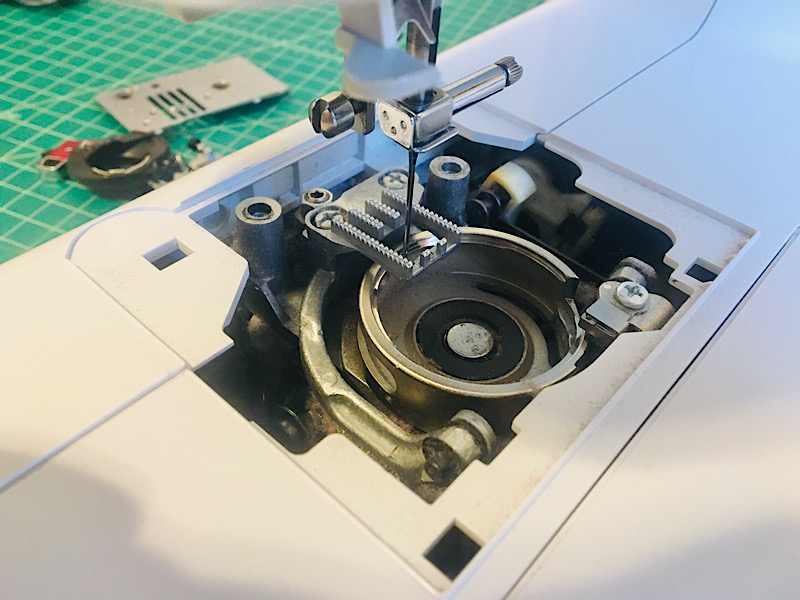

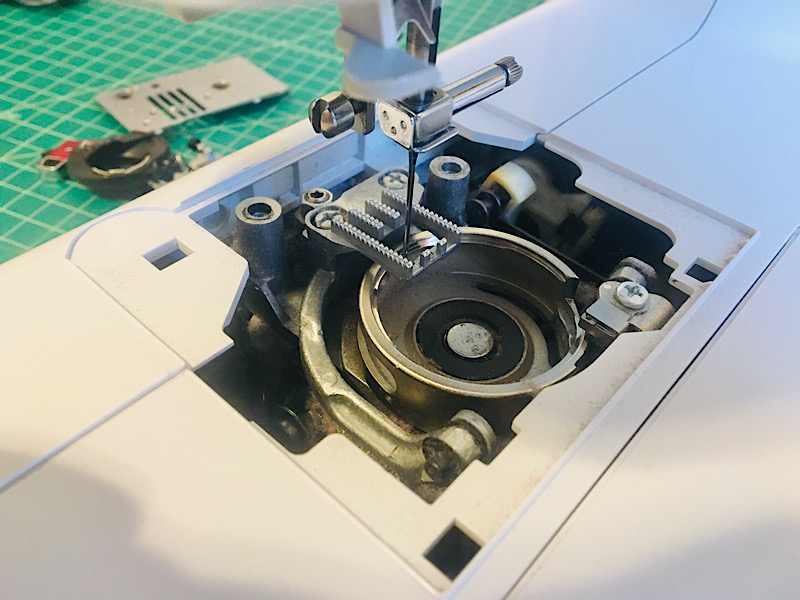

3. Clean the lint from your feed dogs

You can follow your manual’s instructions to remove the needle plate and take a peek inside. There could be material or lint building up and preventing proper motion of the feed dogs.

How to clean around your feed dogs

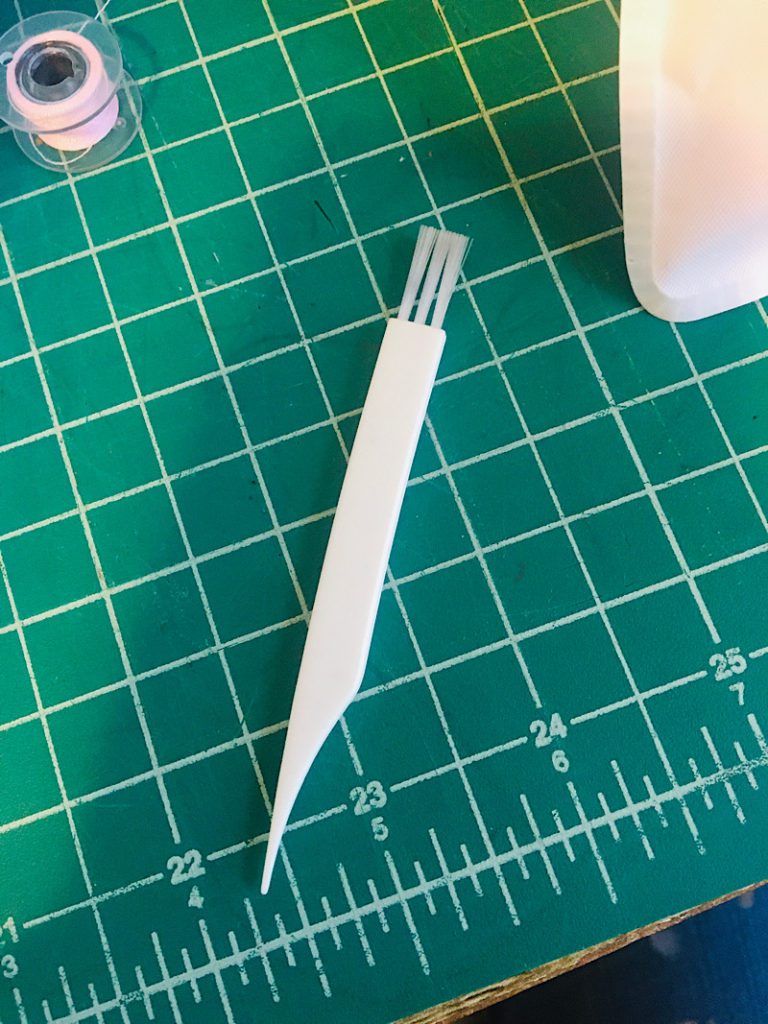

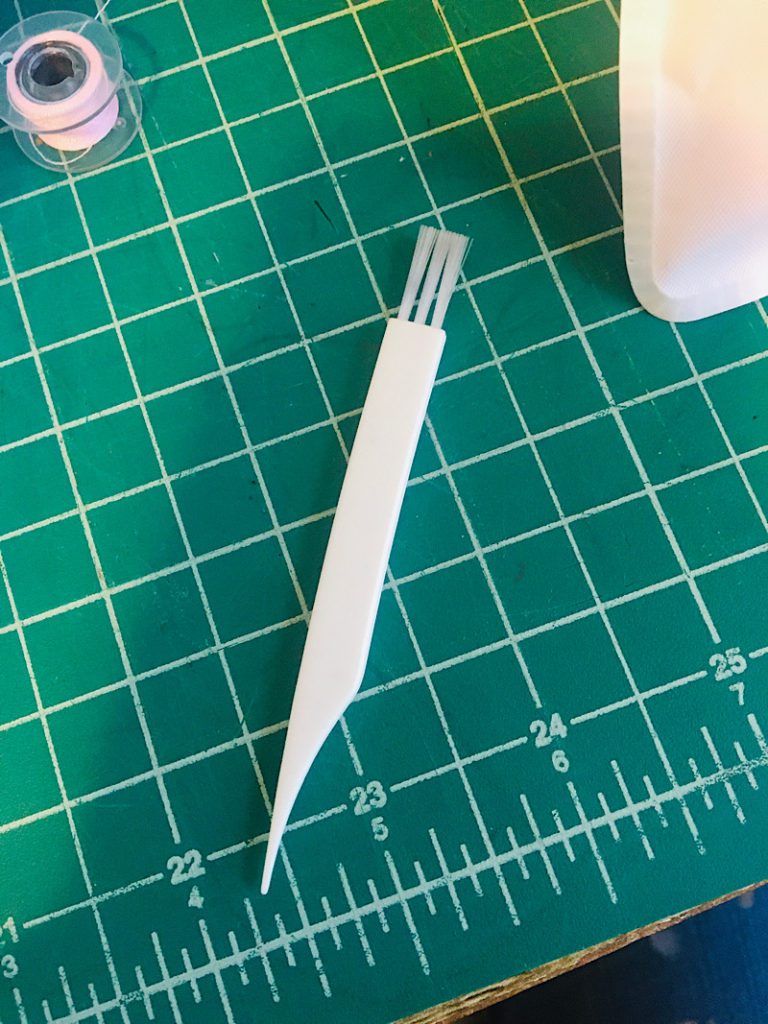

Many sewing machine kits come with a tiny brush.

You can use this brush to gently brush away the lint around the feed dogs and inside the machine.

Be careful not to be forceful or dislocate any of the interior parts of the machine, and make sure to replace your needle plate when you are done.

Cleaning your machine frequently will prevent lint buildup and help your feed dogs work properly!

I hope this information and troubleshooting guide has helped you understand your feed dogs better. They are a small part of your sewing machine but affect it in a big way!

Make sure to learn about the other 24 basic parts of your sewing machine!

What other questions do you have about feed dogs? Let me know in the comments!

I have a Finesse 803 Sewing machine. The fabric will not feed through and only stays in no motion position. I don’t believe machine has a dropcfeeddog option. I assumed it did. What can I do to make it work again.

Hennie, If you want to send me an email then I can try to help you trouble shoot it! Did you try adjusting the stitch length?

I have a singer 66 (red eye) that the feed dogs only go up and down, won’t move side to side. I have tried everything that I know with no results. The dogs are not stuck, and are the proper height. Please give me your insight on this problem, it will be greatly appreciated.

David my first instinct is to have you check stitch length. Raise it all the way up to see what happens.

I’m not an expert with the vintage machines, but if the stitch length isn’t the problem I would assume there is an internal issue needing oil or mechanical repairs.

My feed dogs are moving the fabric to make a stitch, but the fabric is moving back again, so the next stitch is in the same place…piling on stitch after stitch in the same spot. Does this mean the presser foot isn’t tight enough, or is there something else going on?

Update…I now realize my feed dogs are moving back and forth, but not up and down. I guess this would explain why each stitch ends up in the same place. Any ideas? Does something need oiling?

Susan, My first guess would be to check your stitch length!! Make sure it is not at zero.

My Janome SMD 500 has no lever to raise the feed dogs.

a Pfaff 1199 has no movement of the feed dogs whatsoever. I’ve taken the covers off, cleaned and lubricated the machine thoroughly, but still no good. There was loads of debris stuck to the feed dogs and in the bobbin area. What do you suggest I try next?

Caroline, can the hand wheel crank still or is it jammed as well? If the handwheel still works, the feed dogs may have an inner spring or mechanism that is stuck or damaged some how. If the hand crank can’t still turn and raise the needle, I would guess something is jammed.

The hand wheel works fine and so does the needle…it’s just the feed dogs that are stuck in the lower position.

Caroline, I’m assuming you did all the basics like check the feed dog lever, stitch length, buttonhole lever? At this point, you might be best taking it in to be seen!

thanks!

Hi I have a baby Lock sewing machine

After sewing then I try take material away from sewing it

Material or thread is catching in feed dogs why?

Hi Donelda, If the feed dogs have a burr on them, or if the fabric/thread is quite delicate, it could snag.

Hello, I have a singer heavy duty and my feed dogs go up and down, but don’t actually pull my fabric through. This has caused lots of skipped stitches and I’ve already checked stitch length, made sure the feed dogs were up, but I’m not sure what else to try, any suggestions?

Thanks!

I have another post that is more geared towards that problem, maybe it will help: https://seamwhisperer.com/fabric-not-moving-sewing/