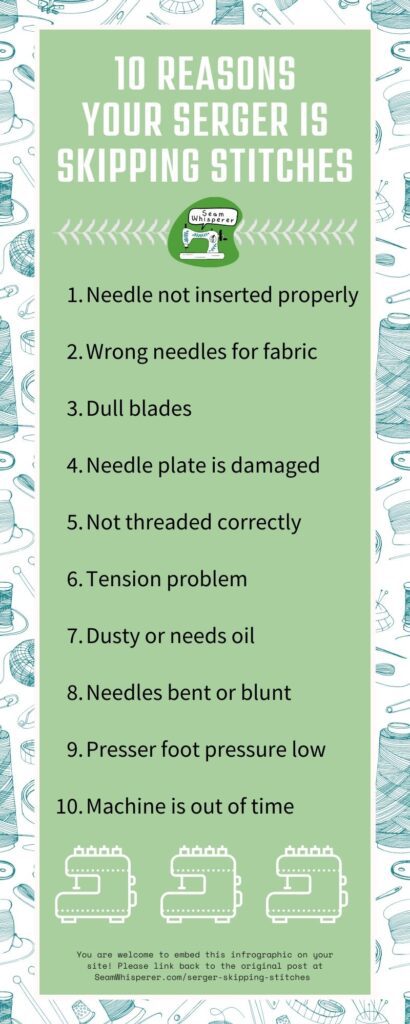

Are you having issues with your serger skipping stitches? This is a frustrating problem because it isn’t always immediately evident what is causing the stitches to be skipped.

So what does cause a serger to skip stitches?

Some of the most common reasons sergers or overlockers skip stitches include: the needle not being inserted high enough, needles being bent or dull, inappropriate thread tension, and dull knives.

But these are only a few of the reasons! Keep reading to find several more, and their solutions!

This post may contain affiliate links. Read the full disclosure here.

Why Is My Serger Skipping Stitches?

1. The Needles are not inserted properly

Improper needle placement is one of the top causes of skipped stitches.

The needles (or needle, if you have a single needle model) on your serger should be properly seated, meaning they are as high as they can go, and they are facing forward. If they are slightly out of place, it can cause many problems (including skipped stitches.)

Even if you haven’t recently ‘messed with’ your needles, it is worth checking that they are inserted properly. Over time they can become loosened.

Loosen the needle screw and remove the needles, then re -insert then carefully. Then try to serge a line on some material to see if that solved the problem.

2. You’re Using the Wrong Needles

Many domestic sergers use needles that are interchangeable with other machines, but if you have replaced your needles, it is worth checking your manual to make sure you replaced them with the right ones.

If the needles are too long or too short, they wont meet with the lower loopers properly and won’t make stitches correctly.

Also, you need to make sure you are using the right needles for the type of fabric you are using. Thicker materials like denim need heavy duty needles, otherwise the needle might have trouble getting through the material (which could cause a stitch to skip.)

Thin or slipper materials need their own needles as well, to make sure the needle is piercing through the fabric instead of puncturing a hole.

If you don’t have your serger manual any more, you can do an internet search for your model and the word “manual” and find it online to easily check what needles your machine and fabrics need.

3. A Blade is Dull

This problem seems unrelated, but trust me, it actually isn’t!

A dull blade can snag on or push down on the fabric causing it to pull backward or to the side slightly. When this happens, it can cause skipped stitches!

Check your manual for instructions on how and when to replace your blades.

The manual for my serger (Brother 1034D) says this:

“Worn or blunt knives will cause… stitches to be uneven. If one strand of thread can be cut off in from or at the rear of the knife, the knife is sharp enough.”

Brother 1034D Manual

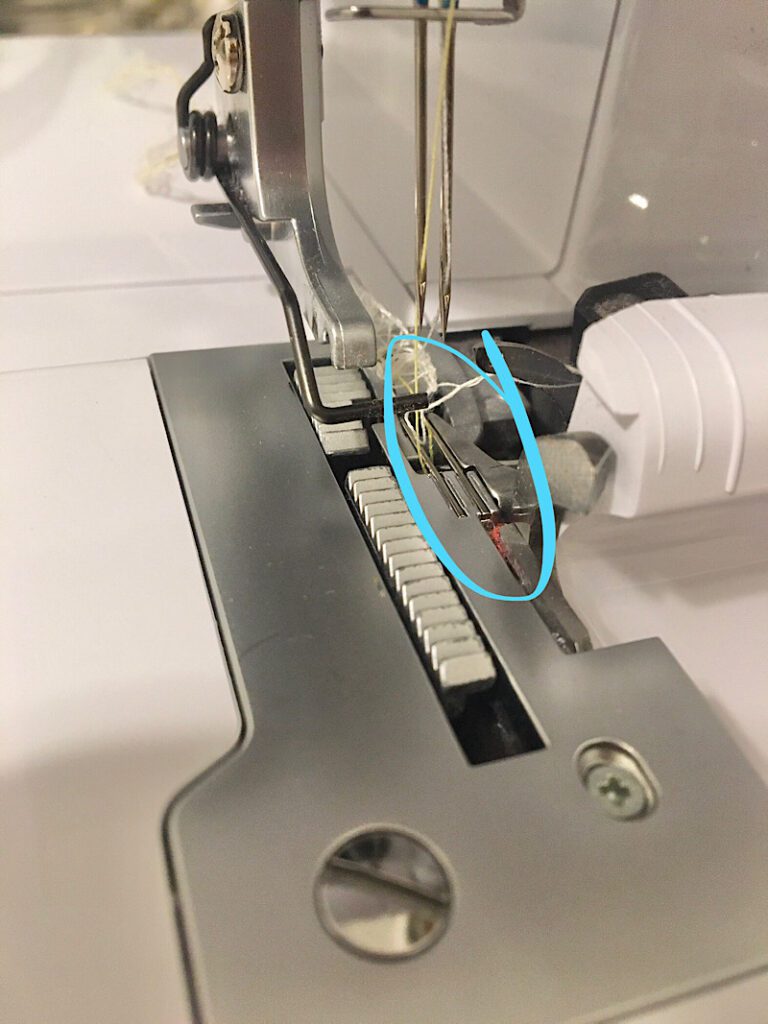

4. Needle Plate Is Damaged

If your needles have ever hit the needle plate and caused a dent, the dents can cause threads to snag or not glide smoothly through the needles. Hello skipped stitches!

If you determine needle plate damage is what is causing this issue for you, then you will need to order a replacement part for your machine. You can order the specific parts from the manufacturer, or from specialty sewing machine parts stores.

Or you can take the machine in for professional repair, but it will likely cost more.

5. The Machine Is Not Threaded Properly

Sergers have a lot of complicated loops and hoops the threads have to jump through, literally! If the threads are slightly askew or being twisted or pulled, it can cause missed stitches easily.

One common threading mistake is to not thread your serger in the correct order. Take the time to unthread your machine and carefully rethread each thread through the tension dials in the correct order to rule out this easy fix!

6. You Have A Tension Problem

Not only can too high of tension settings cause broken threads and bunched fabric, it can cause missed or skipped stitches. This is because the thread pulls so tightly that it does not slide freely through the needles and loopers as they move.

Most sergers have the default tension settings marked with dashes to let you easily reset them without having to consult your manual. Check to see that none of the thread tension dials have been bumped onto a high number on accident, and if you do need to adjust them for certain fabrics, make sure to turn them back down again when you’re done.

7. The Machine Needs to be Dusted or Oiled

When was the last time your dusted or oiled your machine?

Crickets?

Many home sergers recommend being oiled once or twice PER MONTH–or even once per week if you use it quite often!

In addition, the lint that builds up inside the machine can really get in the way of the moving parts.

Give your machine the cleaning and maintenance it deserves, and it will serve you well! Not oiling the machine causes the rotating and moving interior parts to not function smoothly, causing skipped stitches (and many other potential problems!)

8. The Needles Are Bent or Blunt

A sharp needle will easily pierce through the fabric it is intended to work with, allowing the needle threads to be chained together with the thread from the lower loopers.

Needles that are bent or blunt (perhaps from being worn out) won’t be able to pierce through the material, which means the threads won’t go through the needle plate to chain together with the loopers.

If you have been using the same needles for a while, it might be time to replace them and see if they were the reason your threads were skipping!

9. Presser Foot Pressure is Too Loose

The presser feet on an overlocker are very important because a serger works very fast! (Making up to 1300-1800 stitches per minute!) If the pressure on your pressure feet is too low, the fabric won’t be held down properly for the needle to pierce through.

In addition, when the pressure is too low, the fabric has the tendency to slip and slide around instead of letting the feed dogs evenly pull it through. It goes without saying that your fabric needs to be held in place for the stitches to be even!

To adjust the presser foot pressure, twist the presser foot knob (it looks like a large screw on the top left of the machine) and make some test stitches to see if the fabric is held in place better.

10. The Machine is Out Of Time

The final potential cause of skipped stitches on this list is also the most serious, your machine could be out of time.

The timing on a sewing machine or overlocker is essential. The needle above and the loopers below have to move in unison at the correct timing or they will not meet to make the chain.

If your machine is out of time, it will likely need to be professionally serviced. You could watch a DIY video and try to do it yourself, but it is risky if you have no experience and could void the warranty.

If you have tried all else on this list, it’s probably time to make the call! Make sure you know how to locate a good sewing machine repair service.

Conclusion

If your serger is skipping stitches, don’t throw it out the window just yet. (Do you know that feeling?) As you can see there are several simple solutions you can try before taking your machine in for timing repair. The most likely culprit is a needle or threading issue!

Keep in mind, that many of these issues not only cause skipped stitches, but can also cause broken needles on your serger, so even though these are simple fixes, they are important ones!

I hope this solves your skipped stitches! Comment below with which one solved it for you.

All you have to do now is unpick your work and start it again, and you’ll be back to great serging in no time!

Wonderfսl

I cant wait to read far more from you.

Thanks!

Thank you!!! My foot pressure was too loose!

Laura I am so glad you figured it out!!