Are you having trouble with your sewing machine not picking up the bobbin thread? In this post I will dive into the different possible causes to help you solve this problem once and for all!

This issue has happened to me several times, and it drives me nuts!

Especially when the machine seems to be sewing fine, then all of the sudden, RIGHT in the middle of a seam, several stitches are skipped due to the bobbin thread not being caught for some mysterious reason.

Because there are so many parts of a sewing machine that have to work in harmony to make consistent stitches, there are a lot of things you need to check and troubleshoot to solve the problem of bobbin threads not catching.

A sewing machine that isn’t catching the bobbin thread may have a hook timing issue, dull needles, incorrect thread tension, or you may be using fabric that is too thick for your current needle.

But there are actually even more causes than just those. Lets go over the various potential causes and get this problem solved!

This post may contain affiliate links. Read the full disclosure here.

Why is my sewing machine not catching the bobbin?

Lots of these solutions are things that are so simple they seem silly to even check… but they are the first things to rule out in the case of an issue!

1. The Upper Thread Is Too Tight or Needs Rethreading

When you are threading your machine, make sure your presser foot is in the “up” position, so that the thread passes easily through the tension disks.

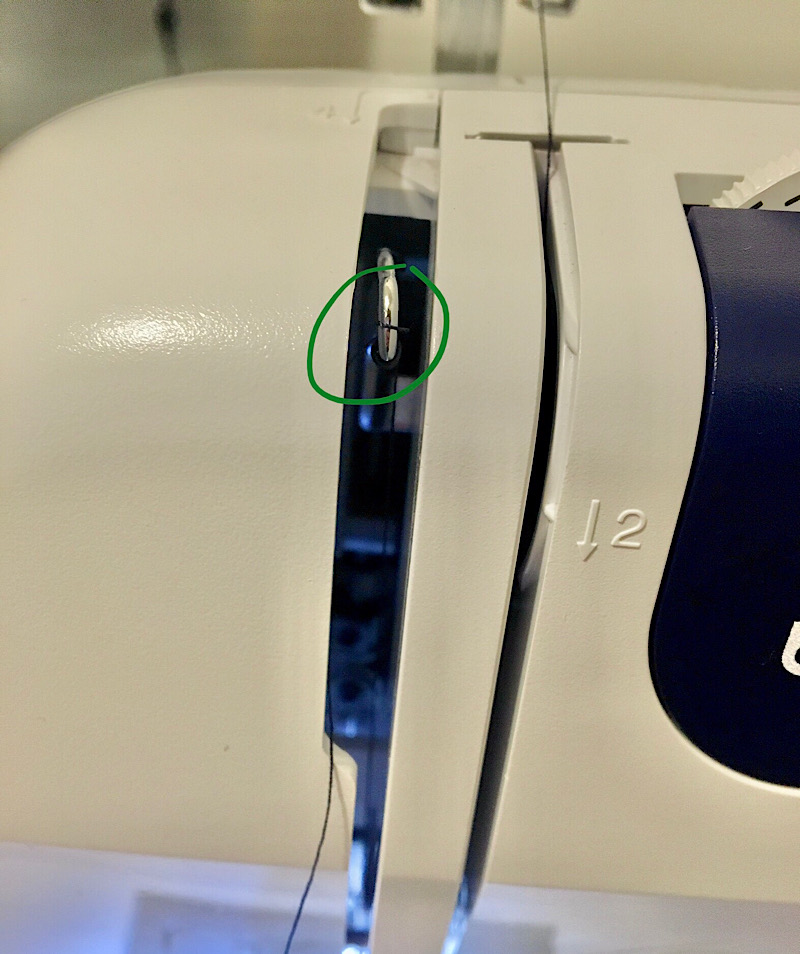

Also make sure the thread is not accidentally wrapped around the thread take up lever (number 7 on my Sewing Machine Parts Printable Diagram). This happens to me sometimes, and causes the thread to tighten and prevent the needle from moving properly.

You also want to make sure the needle is threaded from front to back, and the thread is not knotted around the needle.

2. The Needle Is Damaged or Installed Incorrectly

When inserting the needle, it needs to be pushed as high as it will go into the needle housing. Make sure the flat side of the needle is facing the back, and the needle isn’t twisted in any way.

You also need to make sure your needle isn’t bent. Look at your needle from the side view to see if it is bent at all and replace it if it needs to be.

3. The Bobbin Case And Bobbin Need To Be Checked

After checking your needle, you can troubleshoot the bobbin itself.

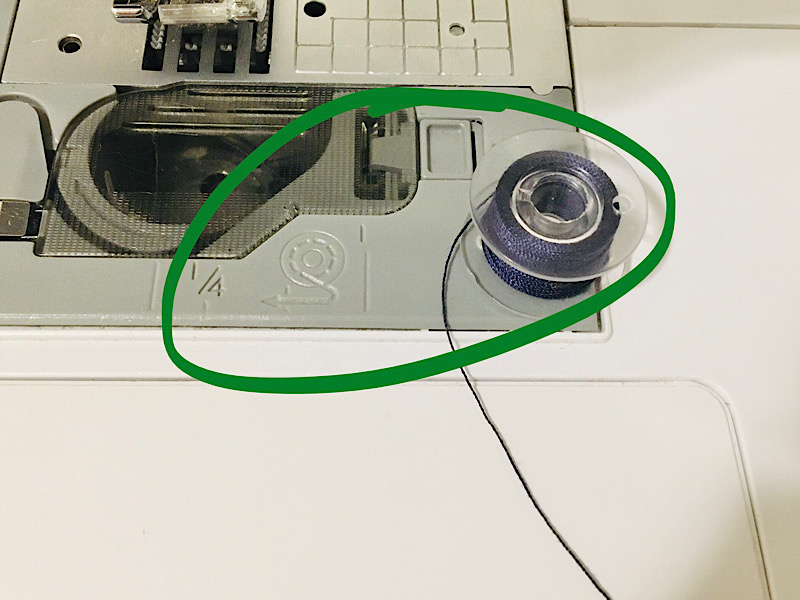

Make sure your bobbin is inserted correctly, not backwards. Different sewing machines require the bobbin to be inserted with different orientations, so check your manual if you need to remember.

It should be wound evenly, with the thread pulled under the pretension. Make sure the bobbin is the right size for your machine (no, they are not universal!) and make sure there isn’t lint in the way of the mechanisms.

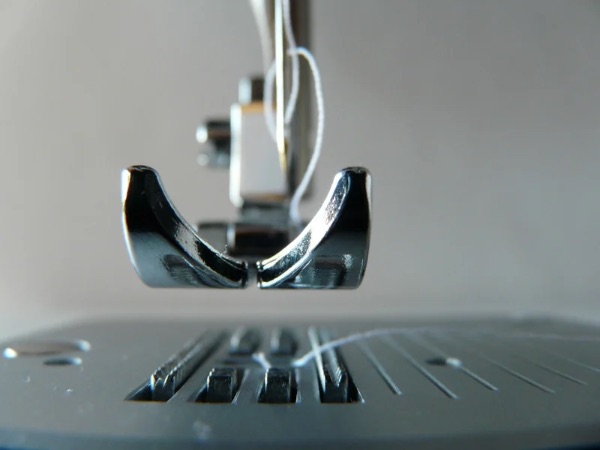

Also check around the bobbin case, the needle plate, and presser foot for any burs, scratches, or dents that could be causing the thread to get stuck. If your needle hits the plate and leaves a scratch, it can catch on the thread.

4. The Fabric Is Too Thick

This is the most common reason MY sewing machine doesn’t catch the bobbin.

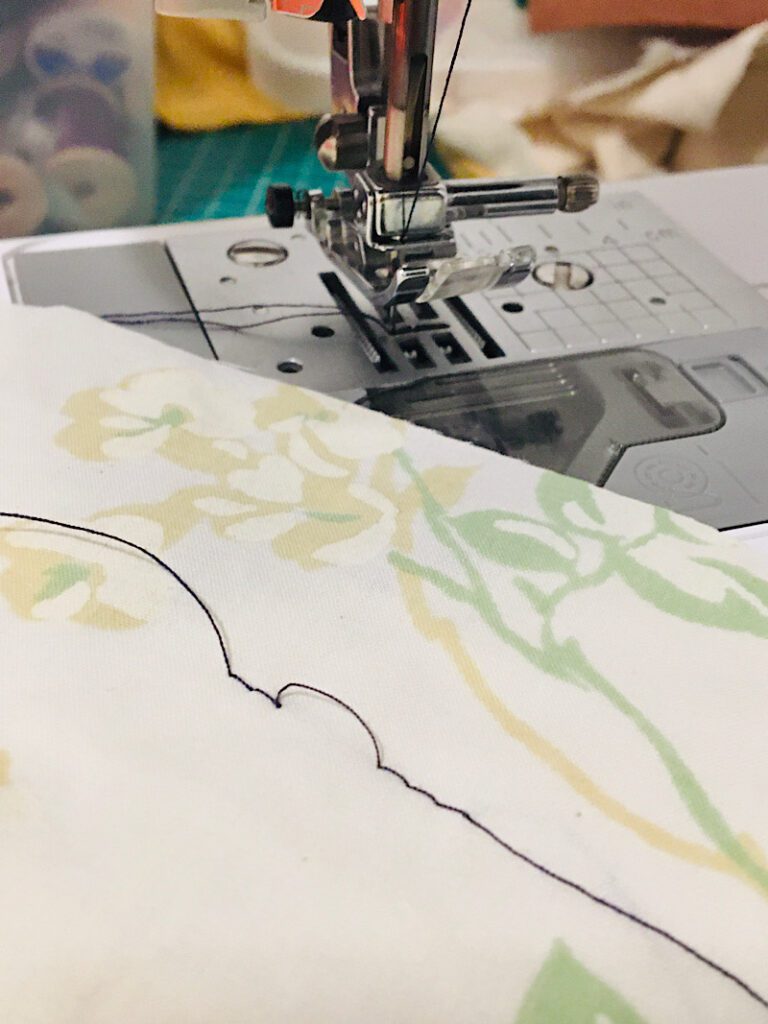

Sometimes, when you are sewing through very thick fabric such as a fat quilt, or sewing over multiple folded seams (like on jeans), the needle has trouble piercing all the way through the material fast enough to reach the bobbin in time.

Sometimes the needle can’t even make it through the fabric at all, which causes it to miss the bobbin and skip a stitch. Another possibility is the the friction of the fabric preventing the thread from being loose enough to easily slide through the needle and form a chain with the bobbin.

If this is your problem, make sure you are using the right kind of needle first and foremost. Thicker materials need different needles. Heavy duty needles are not only thicker than regular needles, they also have a larger notch on the back of the needle (called a “scarf”) which helps the needle catch the bobbin thread! Certain needles also have different tips for different types of fabric, (some are rounded, some are sharp).

After you have determined you are using a proper needle for your thick fabric, try making some stitches very slowly by hand turning the wheel a few times. Once you get over the “bump” back to a thinner piece of the project, you can start to sew with the pedal again.

Lastly, you might also consider using a walking foot with thick projects like quilts to help the material move under the needle evenly so the needle doesn’t bend or get blocked.

5. The Needle Bar Height Needs To Be Adjusted

The needle bar on a sewing machine is a long rod or cylinder that holds the needle in place and moves the needle housing up and down.

If you are certain the needle is seated properly, and none of these other solutions helped fix your problem, checking the needle bar height should be done before assuming there is a timing issue.

While there are tutorials online about adjusting the needle bar height, it is typically a repair that is done by a professional who knows what to look for. You don’t want to accidentally make the problem worse!

Adjusting the needle bar height involves opening up the machine and using a screwdriver to loosen, realign, then tighten the bar.

6. The Shuttle Hook Is Out Of Time

Last of all, you may have a timing issue. A timing issue means your needle isn’t meeting the bobbin hook at the correct moment to form a stitch.

Singer has a tip to help you check if there may be a timing issue on your machine. They say to turn the handwheel towards you while holding the needle thread. When the needle goes down, tug on the thread and a small loop should come up through the needle plate (which is the bobbin thread.) Then:

..using the tip of a narrow object like a pencil or scissors, pull the loop up and then pull both threads (top and bobbin) under the foot and toward the back of the machine.

If the above troubleshooting tips did not solve your issues, you may need to have your machine repaired for timing.

Singer.com

If you determine you have a timing issue, it’s time to find a good sewing machine repair shop nearby.

Conclusion

I hope these 6 possible reasons why your sewing machine isn’t catching the bobbin shed some light for you. The most common cause for me when this happens, is sewing over too thick fabric too fast.

Let me know in the comments below which one solved it for you!

Pin this post for later, and join my email list for more sewing tips!

thanks for this post very helpful content use about sewing machine bobbin i like your content and share it

Thank you and youre welcome!

Just want to thank you fir your help its. amazing how simple your answers to my problems Thanks again as Libby from Ohio May God Bless you.

I am so glad it was helpful to you libby, thank you for your sweet comment!

thank you very much really appreciate it 🙏💯☑️

thanks for the post it really helpful nd I really appreciate that

Youre welcome!

Thank you! I wanted to throw my machine last night. ( I think we have all been there right?!) I will try these tips and hopefully not have to send in my 15 year old $70 machine for repairs lol.

You’re so welcome!!