If you’re trying to wind a bobbin in vain and the winder is driving you CRAZY, check out these 7 possible reasons it might not be working right!

There’s only one thing worse than not noticing you ran out of bobbin thread, and that is not being able to wind a dang bobbin! I have dealt with this before, here are some easy things you can check to fix the problem.

This post may contain affiliate links. Read the full disclosure here.

7 Reasons Your Bobbin Winder Isn’t Working

This list moves through most common, to less common. So start with number one and move through the list as you check each item off!

1. The Machine Is Not Threaded Properly

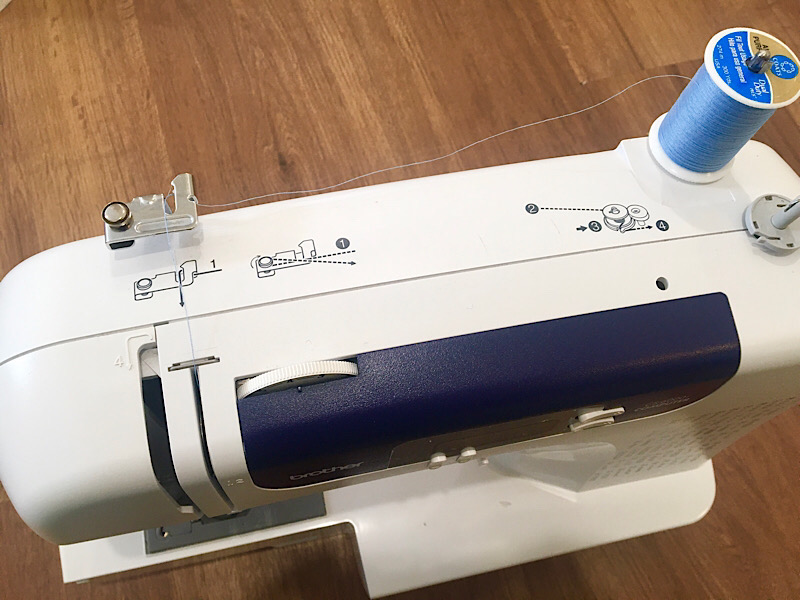

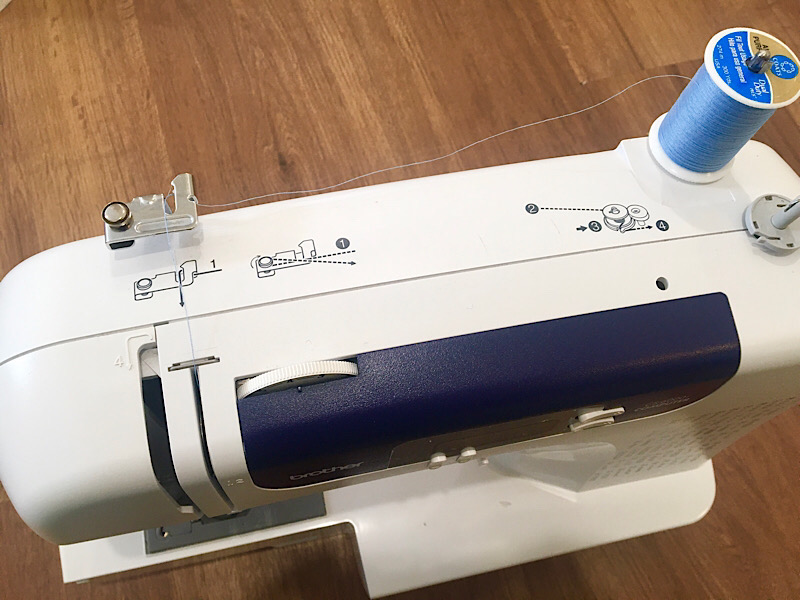

The way a sewing machine pulls thread through when it winds a bobbin is a bit different than for when it is sewing. You need to make sure your thread is following the bobbin winding path, not the sewing path.

Unthread the machine, and rethread it before trying again. Also make sure the thread is wrapped around the correct side of the bobbin when it is placed on the winder. This is different for all machines, so you will need to check your manual.

2. You Aren’t Using The Right Size Bobbin

Bobbins are not universal. Plastic and metal bobbins are not interchangeable, and bobbins also come in different sizes. The center hole may be too large to fit on your bobbin winder, which prevents it from being able to wind properly.

Here is a really interesting chart with different bobbins next to each other so you can see how different they all are!

Make sure you are using either the original bobbins, or appropriate replacements.

3. The Bobbin Winder Is Not Engaged

Before winding, your bobbin winder needs to be engaged, typically this is done by sliding the winder to the right. Some machines have this instruction written on the machine so you never forget.

If your machine engages differently, you will need to consult your manual.

Also remember to disengage the winder by sliding it back after you are done winding.

4. The Bobbin Is Not Correctly Loaded

Make sure your bobbin is all the way pushed down until it is held tightly in place by the little wire or plastic piece on the winder that gives it pressure.

If the bobbin is not pushed down far enough, it can catch on the bobbin stopper and prevent it from spinning.

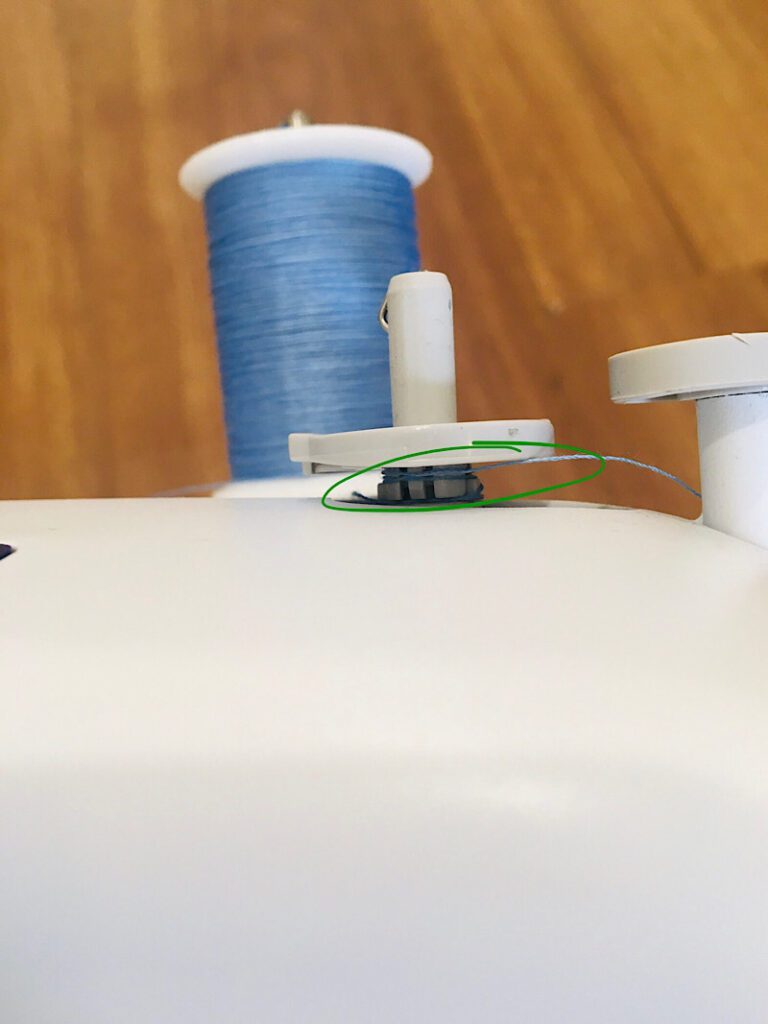

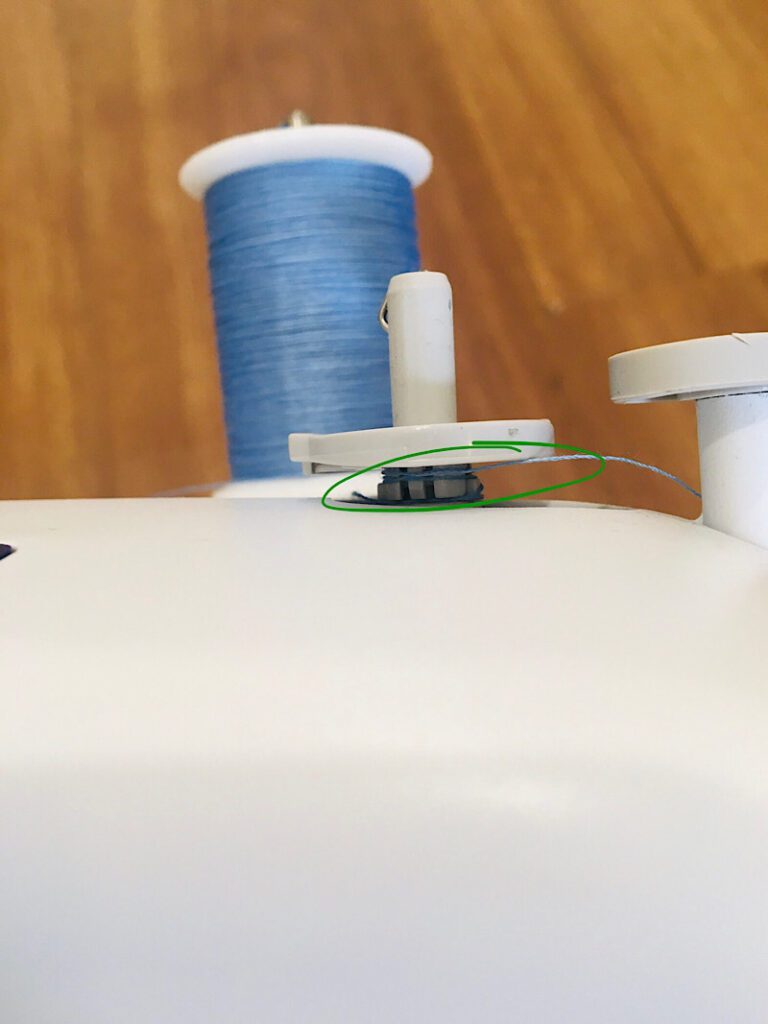

5. The Bobbin Winder Is Jammed

Sometimes the thread gets wrapped around the bottom of the bobbin winder underneath the little plate/base the bobbin sits on. If enough thread gets wrapped there, it can prevent the winder from spinning and cause a jam. The thread will need to be removed, either by unwrapping it (which can be tedious) or carefully slicing through it.

On some machines the bobbin winder base can be removed and the thread can simply slide off the top, then you can pull off the thread and slide it back down.

Make sure to align the base correctly when you re install it.

6. The Winder Stopper is Out Of Place

Notice the little plastic thingy next to the bobbin winder? That is called the bobbin stopper, and it helps stop your bobbin from spinning when it is full. Don’t try to wind your bobbin more than the stopper will allow.

Sometimes, they can come a bit loose, and can stick too far into the bobbin area, preventing the bobbin from spinning smoothly or at all.

The bobbin winder stopper should be sticking into the bobbin just a little bit, so that the bobbin winds to almost full, but there is a small gap around the perimeter.

Place a bobbin on the winder, and position the stopper to the right place. Then use a screwdriver to tighten the screw on top until it is nice and tight!

7. The Handwheel Is Not Popped Out

I saved this one for last because it really only applies to older sewing machines. In addition to your machine being engaged, your sewing machine may require the handwheel to be pressed in or popped out to place the clutch in the right position.

If you have a newer sewing machine, this probably won’t be applicable to you.

Alternative Ways To Wind A Bobbin

If your bobbin winder STILL isn’t working after all this, you have a few options short of taking it into a shop for repair.

1. You can wind the bobbin by hand. This will take a while, and you need to make sure it is wound taut, but not too tight, and is as even as possible. I recommend placing it onto the machine’s bobbin winder after winding to make sure you haven’t made it too full.

2. You can buy a bobbin winder. (Such as a side winder). These are little electric machines that only wind bobbins, and are typically under $30 online.

I hope this post was useful to you, if you found another solution to your bobbin winding issue, leave a comment below to let others know!