Is your serger driving you CRAZY? Here are five reasons why it won’t chain… and what to do about it.

I have to admit, I have very few problems with my serger not chaining, (I really like my Brother 1034D model!) but it HAS come up a few times. Luckily it is usually an easy fix.

The most common reason why sergers won’t chain is because they are improperly threaded. You should also check that the needles are not twisted or inserted too low.

Today I am going to walk you through several more possible reasons why your serger won’t make a chain, and what steps to take to fix the problem.

This post may contain affiliate links. Read the full disclosure here.

5 Reasons Your Serger Won’t Make A Chain

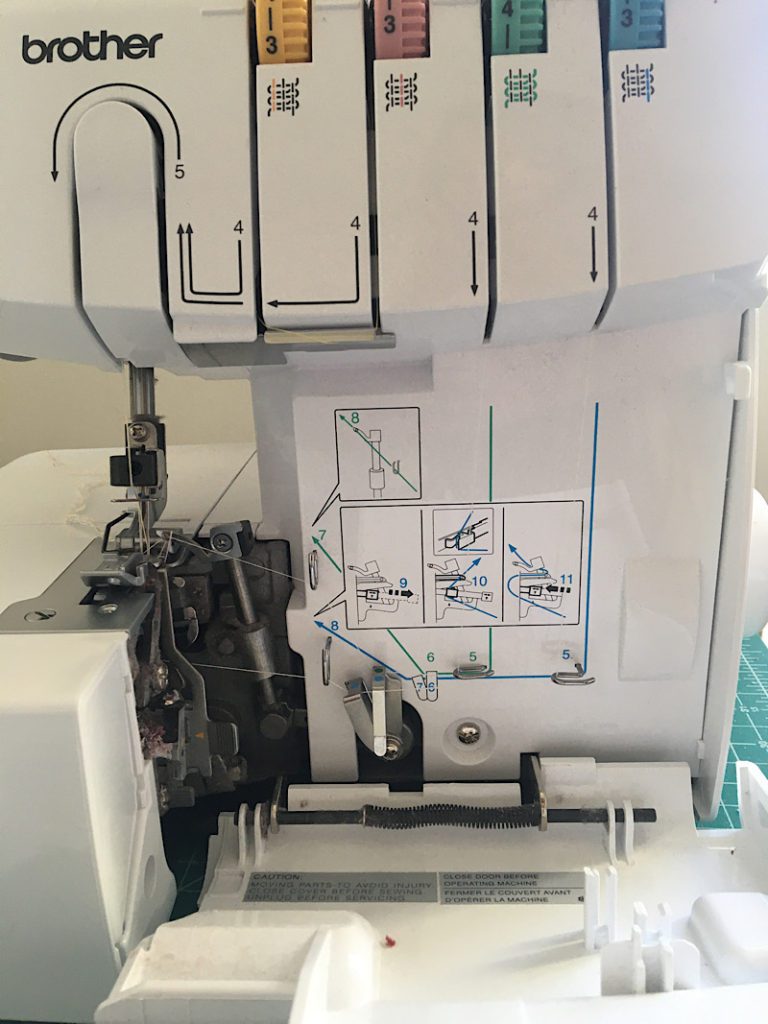

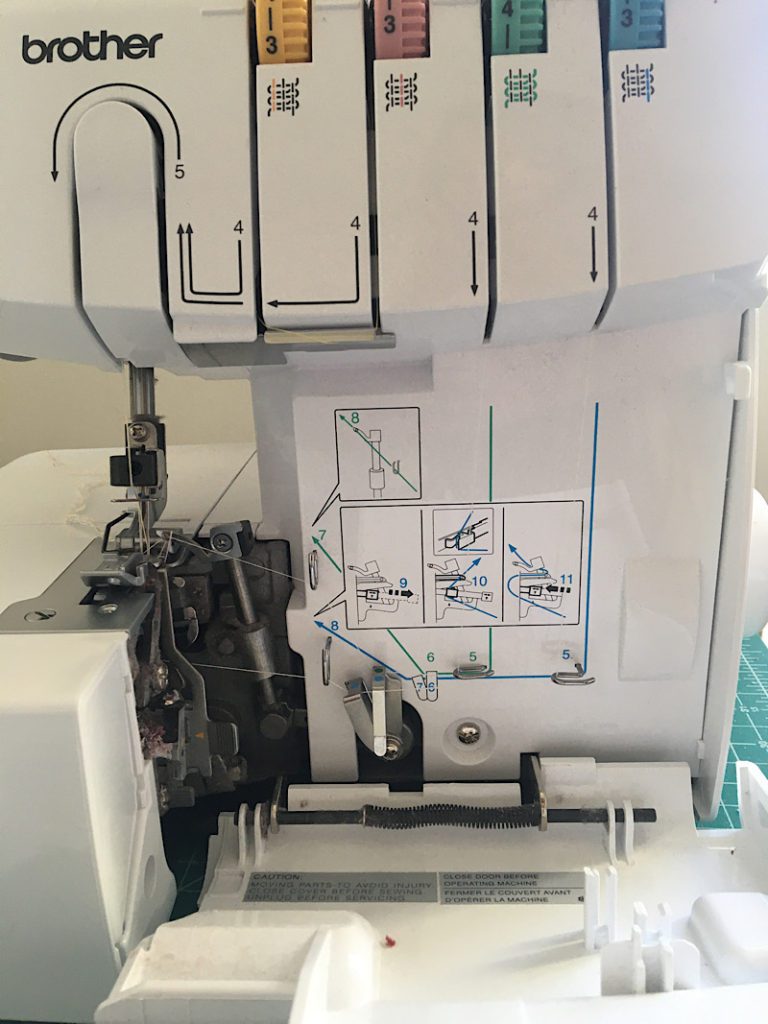

1. You Threaded The Machine Out Of Order

Almost ALL chaining issues I have ever had are really threading issues.

You may have already re-threaded your machine 20 times, but it really is worth starting from scratch again. Let’s walk through it together.

- Completely remove every single thread from the machine.

- Spin the Tension Dials all the way back down to 0, then put them back into their usual setting (3-5 is typical)

- Take out your manual if you have it, and follow the steps to the letter!

You should make sure the thread tree is all the way up, and the thread spools are lined up straight with the tension disks. You should also raise the needles to their highest position by turning the wheel TOWARDS you.

Serger threads HAVE to be threaded in order, otherwise the looper threads will not be able to form chains around each other correctly. The lower looper MUST be threaded under the upper looper.

The correct order is always:

- Upper Looper

- Lower Looper

- Right Needle

- Left Needle

(I remember this by saying 3 4 1 2.)

Once you have done this, and the problem still exists, then move on.

2. You Haven’t Checked The Needles

When the needles of a serger lower underneath the plate, they do so at the exactly right time to meet up with the two loopers, which wind a thread around and create a chain stitch.

In order for this chaining to take place, the eye of the needle has to be in the righ place at the right time.

Check your needles.

- If the needles are too short, the eye of the needle with the thread won’t drop low enough to meet the loopers.

- If the needles are not pushed all the way UP in the needle housing, they will drop TOO low. (Loosen the set screw a bit, push the needles all the way up, and retighten)

- If the needles are in any way bent, bumped, or twisted, replace them!

(Note, it is normal and correct for the right needle to be slightly lower than the left needle even when inserted correctly)

Needle insertion issues are probably the second most common threading issue on a serger. So cross this easy one oft the list too!

3. The Tension Is Having Problems

Did you know that when you lift the presser foot on your serger, it opens up the tension disks? If you are not lifting up your presser foot when you thread your machine, the threads may not properly be caught in the tension tracks.

So, when threading your machine, make sure to lift your presser foot!

In addition, some sergers (like mine) have a little button called the tension release button located right above the tension dials on the top of the machine. When passing the thread through the dials, you have to press the release button in order for the thread to correcltly slide through the tension dials.

Why is tension a problem with chaining? Because if the tension is incorrect, it is easy for the looper threads to break and come unthreaded without you noticing. This has happened to me before. If one of the looper threads catches on another thread, or breaks, then the machine won’t chain.

(Note: your machine WILL still chain if one of the needle threads breaks. I previously demonstrated that it is still possible to serge with only 3 threads on a 4 thread serger, as long as both loopers are correct.)

4. The Machine Needs To Be Cleaned

When was the last time you oiled your machine? What about clearing away lint?

When the knives trim away material as you serge, a lot of lint can build up. Underneath the needle plate you will be able to see lint build up, and this build up gets in the way of the loopers and needles when the come together in time to form a chain.

If a ball of lint is in the way, it can prevent the needles from lowering properly, as well as blocking loopers from moving smoothly. This issue seems minimal, but it is actually a big deal because over time a dirty machine can actually cause timing issues!

Most sergers come with a little lint brush that can be used to brush lint away from the looper and knife area. Unpluf y your machine and take the time to clean it out.

You should also be following your manual’s instructions to oil it regularly. If the inner mechanisms of the machine are not lubricated, they can catch and also causing timing issues, which will prevent chaining.

Only use sewing machine oil to oil your machine, and if you’ve never done it before or don’t know how, look in your manual.

5. The Machine Is Out Of Time

The last possible reason is also the one you don’t want to hear… but if you have sincerely tried everything else and your serger STILL won’t chain off, then you may indeed have a timing issue.

If your machine is still within it’s warranty, I would recommend reaching out to the manufacterer or the authorized retailer you got it from to see if they can service it for a reduced cost or even free.

Determening and fixing a timing issue on a serger can sometimes be expensive, so make sure you try everything else on this list fist.

And, it is worth mentioning that although some DIY videos so exsist online, I don’t recommend DIYing a timing fix if you don’t know how. It can void your warranty and even make things worse, which is no fun!

If you need help locating a high quality sewing machine repair shop, you can look over my guide of where to find one.

Conclusion

I hope you were able to find a solution for your machine’s chaining problems. Sometimes sergers can be a little bit picky!

If this was helpful to you, consider leaving a comment and subscribing to my newsletter for more sewing tips and content!