Is your sewing machine refusing to make stitches or make them properly, no matter what you try? Here are 8 common reasons why this happens and how to fix it!

One of the most annoying problems I have faced when sewing, is when no sewing happens at all! Have you been pressing the foot pedal, only to watch the needle move but no stitches be made?

When this has happened to me, it has driven me crazy. But it is a fixable problem!

The most common reasons a sewing machine isn’t stitching are that it is not threaded correctly with the right combination of thread, needle type, and fabric; and that there is a tension problem.

There are several other causes for this issue as well, so make sure to read them all to figure out how to solve it for your situation!

This post may contain affiliate links. Read the full disclosure here.

Why Isn’t My Sewing Machine Making Stitches?

1. The Top Thread Is Incorrectly Threaded

When you have sewing problems, this is one of the first things you should check in almost every case.

The top thread has to travel off the spool smoothly and wrap around many channels through the thread path before reaching the needle. There are lots of places for it to get caught and snagged if it is not threaded just right!

The thread path includes tension disks and levers that allow the thread to be pulled from the spool evenly and with the right amount of force. If the top thread gets stuck, or misses part of the path, it can have trouble gliding through the needle and prevent a stitch from being made correctly.

Some important things to look for is that the thread is behind the needle bar thread guide, the presser foot is raised as you thread, and that the needle is in the highest position as you thread.

The best thing to do is to unthread the entire top thread, and do it over again just in case!

2. Wrong Combination of Thread & Needle

Did you know that certain threads and needles might not work together? It’s true.

Some sewing machines even come with a thread and needle chart in their manual that will help you select a thread and needle pairing based on what you want to sew.

If you are sewing with thicker thread weights, or thread that isn’t as smooth (such as metallic thread) it will probably need a heavy duty needle or a needle with a larger eye (the hole the thread goes through).

Trying to sew with thicker thread in a too-small needle can cause friction and pulling on the thread as it struggles to glide through the eye. This can cause skipped stitches, lack of stitching all together, and even broken threads.

In addition, if you are sewing a tightly woven material and are trying to use a knit-needle, the needle may not pierce through due to not having a sharp point. This will cause your machine to fail to make stitches.

Check in your manual to see if there is a thread/needle selection chart that can help you.

3. Upper Thread Tension Too Tight

The upper thread and lower thread tensions have to be in balance in order to make a quality and even stitch.

If the upper thread tension is too high, the machine will pull the top thread back too forcefully and it won’t be able to properly loop with the bobbin thread, which will prevent stitching or make skipped stitches.

Thread tension depends on the fabric you are sewing, as well as several other factors, and there is usually a chart in your manual that can help you choose what tensions to use and when.

Note: The upper thread tension dial often has a marking on the recommended settings so you don’t have to reach for your manual each time you want to reset it.

4. Thread Is Getting Caught On A Burr

This is a less common issue, but still worth mentioning. Sometimes when a needle hits the presser foot or needle plate, it can scratch it and leave a burr or indent.

That indent can cause thread to snag and get caught, which will pull it out of the needle and prevent stitches.

Check your presser foot and needle plate with your eyes and your finger to feel for and look for any scratches or burrs that may be grabbing the upper thread.

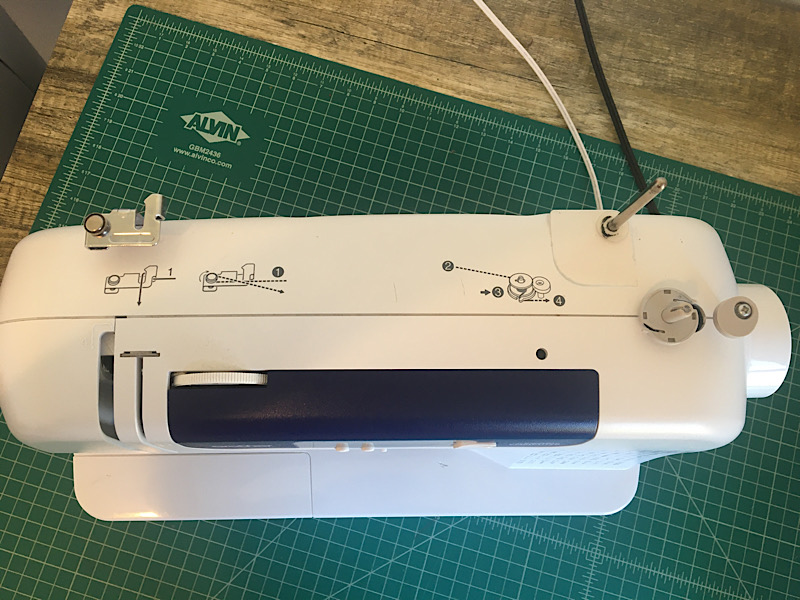

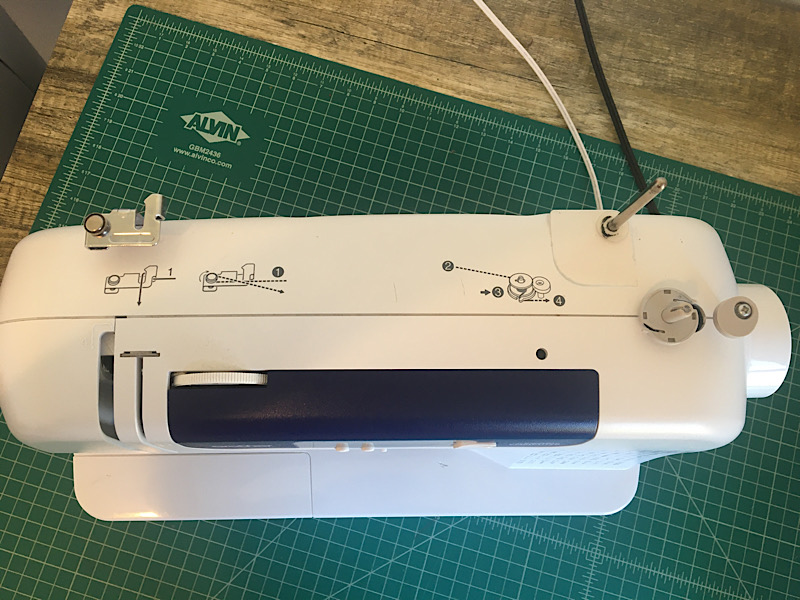

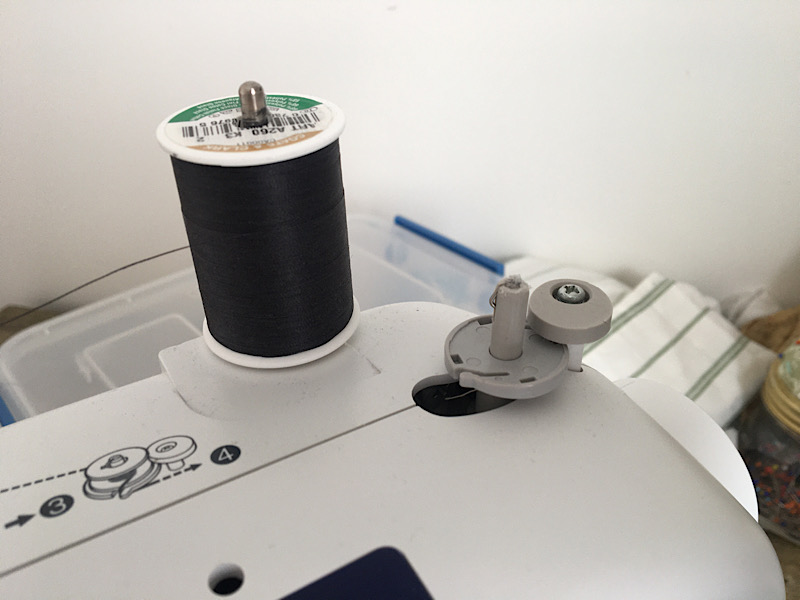

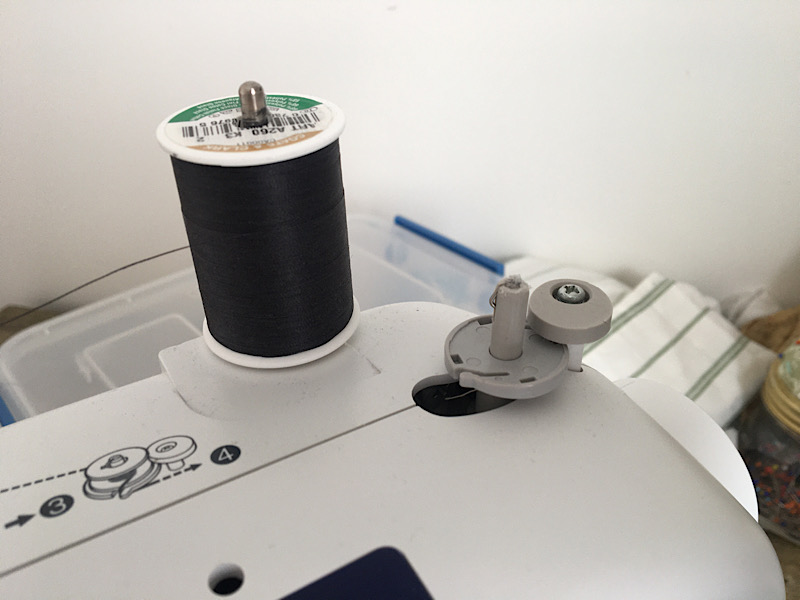

5. Bobbin Winder Engaged

On most computerized machines, your sewing machine will beep or make some kind of noise if you attempt to sew with the bobbin winder engaged.

But, if you have an older sewing machine or another model without this feature and your machine won’t sew or make stitches when you press the foot pedal, check to see if the bobbin winder is in the “winding” position.

If it is, slide it back to its “off” or “disengaged” position so that the machine stops spinning it and raises the needle to sew, instead.

6. Bobbin Inserted Incorrectly

Whether you have a top or front loading bobbin, it has to be inserted correctly in order for your machine to be able to make stitches.

The bobbin must be placed into the bobbin case in the right orientation, as well as the threads pulled around and through the bobbin thread path correctly.

In my sewing machine (with a top loading bobbin) the bobbin is placed so the thread falls off the left side like the letter “P”.

If the bobbin was placed the other way, then it would not unwrap correctly and could cause a bird’s nesting situation, as well as prevent stitches from chaining properly.

Remove your bobbin and reinsert it correctly. Check your manual if you need to remember how!

7. Fabric Is Too Thick

If you are sewing through a particularly thick material or several layers (like in a quilt) your needle may be having trouble piercing all the way through to the bottom to meet the bobbin thread in time to loop together.

Sometimes a thick fabric will slow the needle down, even if it does make it all the way through, but since it has slowed down just enough to miss the bobbin thread, it won’t catch.

If you are sewing thick fabric, first make sure you are using the correct thread, needle, and tension. Then try sewing slower to see if that fixes the problem.

You may determine that whatever you are sewing is just too thick or dense, and you can’t sew it with your domestic machine. You could try using a sewing awl and sewing it by hand.

8. Your Machine’s Timing Is Off

I always save the worst answer for last. If your machine simply wont make stitches and you are sure none of the other reasons are causing it, it might just be that the timing is off.

If the timing is off, even by a little bit, the upper and lower threads won’t pass by each other at the exact right moment needed to loop around each other and make a stitch. This if course, would prevent any sewing from occuring.

You can check if your machine is out of time by removing the needle plate and watching the shuttle hook as you turn the hand wheel. (There are lots of videos online that can show you what to look for.)

If your machine is out of time, it will need to be repaired by a professional service center. You can learn how to locate a good sewing machine repair shop in this handy guide.

Conclusion

When you sewing machine isn’t stitching it can feel like a nightmare! I have had this happen before, but luckily it usually doesn’t mean something major is wrong with your machine.

After checking the basic three (needle, threading, and tension) you can try several other things to see if they fix the problem for you!

I hope these tips were helpful to you!

thanks for helping me to fix my machine

You are so welcome Eileen!

My Pratt 2134 suddenly stopped stitching knit stitches. It stitched woven fabrics, but not knits. I finally brought in to “a guy” I was referred to, and he can’t seem to find the problem. He said “just use the zigzag. It’ll be fine”.🙄 Any ideas (besides not going back to him)?

Hi Lois! I am not familiar with that machine, or the stitches it has. Have you checked to see if there is a digital version of the manual online if you dont have a physical copy?